Plaxall at 5-46 46th Ave. (Photo courtesy of Steven Speliotis)

Aug. 30, 2022 By Christian Murray

Plaxall, a prominent Long Island City real estate company that got its start in western Queens as a plastics manufacturer 70 years ago, has closed its factory on 46th Avenue.

The family-owned company, which was founded by Louis Pfohl as an industrial design firm in 1938, came of age in the 1940s after it pioneered the thermoforming manufacturing process—where it would heat sheets of plastic to a pliable temperature and mold them into custom objects.

Pfohl, an engineer and the originator of thermoforming, opened the 5-46 46th Ave. factory in 1950 and also began to invest in local real estate.

The family has now accumulated more than 1 million square feet of space in the area—including 12 acres of property that it owns by Anable Basin.

Plaxall today is managed by three of Pfohl’s grandchildren, who will focus on its real estate holdings—which has long been the company’s primary business.

“It took the family a number of years to make the final call to close the factory—since it was the start of our business and it was our grandfather’s baby so to speak,” said Paula Kirby, who along with her cousins Tony Pfohl and Matthew Quigley manage the real estate portfolio and had run the plastics operation.

“The [plastics business] over time kept shrinking while the real estate business became more prominent,” Kirby said. She said that in the 1980s the plastics operation had about 200 workers but when they closed the factory last month, they were down to 15 employees, many of whom were ready to retire.

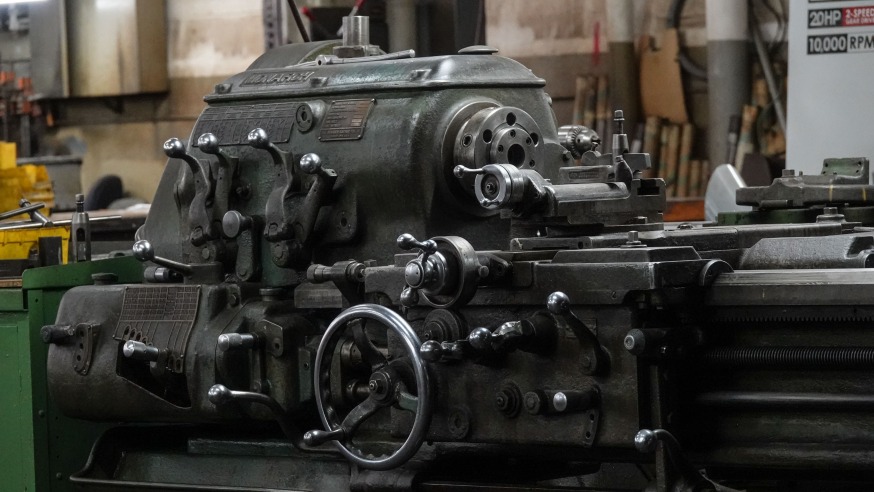

The Plaxall factory in operation earlier this year (Photo courtesy of Steven Speliotis)

The Plaxall factory (Photo courtesy of Steven Speliotis)

Kirby said that today most companies in the thermoforming plastics business operate out of large industrial parks, where they have huge footprints and can be easily serviced by large trucks.

Nevertheless, Kirby said the plastics business allowed her family to invest in real estate in its earlier years. However, over time, it was the real estate that allowed the plastics business to stay in operation.

Kirby said that the greater family had been talking for some time about closing the factory. “It was a longtime coming…but a little over a year ago we made the very emotional decision to close it.”

She said that they informed their staff in July 2021 that they planned to close, and shortly after notified their customers. On July 14, 2022 production at the 60,000 square foot factory came to an end.

LICTalk was first to report that the factory had closed.

One of the machines that is approximately 70 years old (Photo courtesy of Steven Speliotis)

The company has spent recent weeks dismantling the factory and dealing with the large machinery that date back to the 1940s and 1950s. Kirby said that they were initially unsure what to do with the old machines.

“Oddly, it was a big challenge. We were also emotionally attached to some of them—in a way,” Kirby said.

Initially, they thought about selling some of the machines online—although they were aware that they were not mainstream items.

Kirby, however, said that she managed to find a good home for several of them.

Many have been shipped to MIT, where Kirby has a daughter who is studying engineering at the prestigious school.

“I reached out to one of the MIT engineers who was in charge of one of the mechanical engineering labs,” Kirby said. Soon after, two MIT professors visited the factory and wanted to take some of them—which were in turn donated.

One of the old machines is now being displayed at the university next to a solar powered futurist-looking vehicle.

“It’s made many of us happy that the machines will be getting a second life, including our two machinists who are retiring.”

The factory floor is now empty and Plaxall is in the process of starting to market the space for new tenants. Plaxall, however, will retain the office portion of building.

“It’s a great space. High ceilings, heavy floor loads. The space has a lot of possibilities.”

One of the machines that has been relocated to MIT (Photo courtesy of Hayami Arakawa of MIT)